testing plating thickness|eddy current thickness gauge : agent Proper coating thickness is crucial in both functional and decorative plating. Here are some common problems and ways to measure . WEBSeja um cooperado Privacidade e Segurança Cooperativa Central de Crédito Ailos - CNPJ 05.463.212/0001-29 Rua General Osório, 1180, Velha, CEP 89041-002, .

{plog:ftitle_list}

webMira Japonesas Tetonas videos porno gratis, aquí en Pornhub.com. Descubre la creciente colección de películas y cortos XXX Los más relevantes de alta calidad. ¡No hay otro .

Proper coating thickness is crucial in both functional and decorative plating. Here are some common problems and ways to measure . What is the difference between an average, range or minimum plating thickness specification and how do I properly call out my thickness requirement on a print? There are .The protective qualities of platings are proportional to the plating’s thickness, so thicker zinc coatings offer more protection than thinner coatings. For example, materials placed indoors require much less protection than outdoor materials .

The Buyer/User, through its own analysis and testing, is sole ly responsible for making the final selection of the products and for assuming that all performance, safety and warning requirements for the application are met. . Typical thickness of electroless plating can be as thin as .0005" and up to.010". Electroless coatings,

Non-Destructive Testing: These gauges typically employ non-destructive testing methods, which means they can measure the plating thickness without damaging the underlying material. Versatility: They can be .The American Society for Testing and Materials (ASTM) . SC3 or SC4) – to define the minimum plating thickness required according to the type of environment. Service Condition 1 is for mild or indoor applications whereas service condition 4 is for very severe or highly corrosive applications. ASTM B633 Chromate Specifications Type Chart .Sample: One plated area 0.010 inches (0.25 mm) in diameter or larger. Basic Description: ASTM B568 X-Ray Fluorescence (XRF) is a non-destructive method of measuring plating/coating thickness by using an X-ray beam to excite the surface of a sample and then calculating the intensity of the energy returned by the plating versus the base material. Each element emits .

Testing before curing, used in quality control during production, is measuring the thickness of the powder itself before it crosslinks into the resulting, even coating. Two of the methods, involving a comb and a probe respectively, measure the height of the powder – the thickness is determined by factoring the reduction factor against the .Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in coating thickness measurement. Whether single or multilayer coatings, painted or galvanized, magnetizable or conductive.For more than 6 decades, Elcometer have been world leaders in coating inspection and coating thickness measurement, offering a wide range of accurate digital and mechanical dry film thickness gauges. Elcometer's latest innovation, the new Elcometer 456 sets new standards in coating thickness measurements.a non-uniform thickness layer thus exacerbating the problem. The definition of thickness as applied at APC is the purpose of this monograph. Plating Thickness Deposit thickness applied by barrel or rack techniques and by either of electrolytic or electroless methodologies is normally distributed. The normal

The thickness of the coating affects this magnetic response, allowing the instrument to calculate the coating thickness. Compliance with ASTM D7091 ensures standardized, repeatable, and reliable coating thickness measurement, which is essential for quality control in manufacturing and maintenance processes. Ultrasonic Thickness Gauges

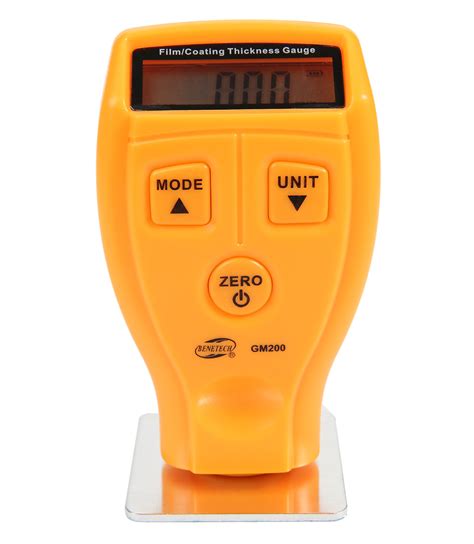

precise coating thickness gauge

Powder Coating Thickness Testing ; Stone Chip Resistance Test; Stone Chip Test; Taber Abrasion; Test; Zinc Plate Thickness ; Zinc Plating Thickness ; In states where Applied Technical Services, LLC does not provide engineering services, engineering services will be provided by ATS Engineering, (P)LLC or a licensed contractor. Maintaining plating thickness as specified by a buyer and applicable standards is critical for the quality and longevity of the end product. In order to be sure that a component’s thickness is correct and consistent, tight controls must be maintained during the entire plating process. A key function to achieving this is accurate plating thickness.

water bottle purification testing videos

The PosiTector 200 Ultrasonic Coating Thickness gage non-destructively measures a wide variety of applications using proven ultrasound technology. Measure paint and coating thickness over wood, concrete, plastic, and more. Advanced models measure up to 3 layers with graphics. Conforms to ASTM D6132 and ISO 2808.Actual plating thickness test results, or a copy thereof, shall be included with each lot. Data shall include all plating layers and all thickness readings. Inspection quantities are defined in Table 1. 5.5 Adhesion. Adhesion of the plating materials shall be tested with a Bend Test inTable 2 indicates that the galvanizing thickness of Coating Grade 100 is 100 microns or 3.9 mils. The weight of the galvanizing is 705 grams/square meter or 2.3 ounces/square foot. Methods for Measuring Galvanizing Weight or .

Regardless of the type of coating thickness instrument used, the end user should be aware of factors that can influence anodize thickness readings. Influences in coating thickness measurement can affect the .Paint thickness gauges, ultrasonic coating thickness gauges, digital thickness gauges and many more options are available to test plastics, glass, ceramics, metal and other materials. Along with coating thickness, it is widely being used for thicknesses of glass, wood, and plastics and also serves as major testing equipment in the corrosion .Destructive testing of thickness is also valuable for coating failure investigations. . Example: The total coating thickness is approximately 10 to 15 mils. Step 2: Select a Cutting Tip. The Tooke Gage is supplied with three cutting tips. They are identified as, “1X, 2X or 10X.” The 10X tip is best used to make an incision into a coating .

plating thickness tester price

Coating Thickness. There are two methods for measuring the zinc coating thickness of hot-dip galvanized steel; a magnetic thickness gauge and optical microscopy. The simplest and non-destructive way is to utilize a magnetic thickness gauge, as optical microscopy is a destructive test only used to resolve measurement disputes.Many organizations require verification of gage accuracy at the test site each time a coating thickness gage is put into service and at frequent intervals during use. Ideal for this purpose, DeFelsko certified coating thickness standards have measured values traceable to a National Metrology Institution. Used to verify the accuracy and .

Coating Thickness Range: Consider the expected thickness range of the coatings in your application. Some instruments may excel in measuring thin coatings, while others are designed for thicker layers. Choose accordingly to meet your project requirements. Measurement Precision: Precision is key in plating applications.The Buyer/User, through its own analysis and testing, is sole ly responsible for making the final selection of the products and for assuming that all performance, safety and warning requirements for the application are met. . Typical thickness of electroless plating can be as thin as .0005" and up to.010". Electroless coatings,

Qualification Testing; X-Ray Evaluation; . It can measure the plating thickness on large and fine-pitch conductors of a variety of plating finishes: tin-lead (Sn-Pb), immersion silver (ImAg), immersion tin (ImSn), electroless nickel immersion gold (ENIG) and thick gold (Au). .

The protection from the zinc plating is proportional to the thickness of the zinc plating - so thicker zinc means more protection for the base metal. Thickness has almost no effect on the resistance to "white rust" because this involves the coating itself corroding. A clear correlation between the de-plating time and the coating thickness arises when the test current and area are both kept constant. De-plating takes place in a measuring cell (miniature electrolytic bath). The measuring area is defined by a plastic gasket attached to the measuring cell. The electrolytes used are formulated for the various .

Example A: Imagine you take a measurement on a steel coil coated with zinc galvanize using a PosiTector 6000 F gage and obtain a single-side thickness reading of “0.35 mils.”This can be easily converted to oz/ft² using the following method: Multiply the gage reading of 0.35 mils by 2 to account for both sides of the panel (0.70 mils) DFT coating thickness portable gauge with interchangeable probes for high phosphorous Nickel on Iron measurements. . Penetration of the coating is limited to 10% of its thickness, which makes it a non-destructive test. HM2000 AND HM500 NANOINDENTERS. Explore Further. Automatic and manual stage Nanoindenters with the load range of 0-2,000mN.

plating thickness measuring instrument

water bottle purity test

water bottle rocket test

Busque por passagens aéreas, reserva de hotéis, aluguel de carros ou seguro viagem. .

testing plating thickness|eddy current thickness gauge